Your cart is currently empty!

Nvember 12, 2021

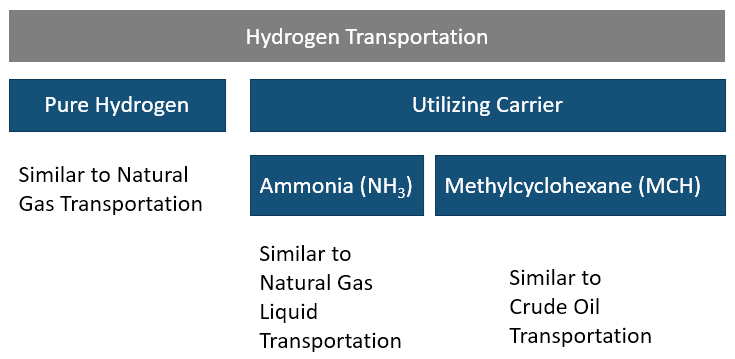

Hydrogen has high energy per weight, however, has low density therefore; low energy per volume. Having low boiling point (-253 degrees C) and low-density results in challenges in storage and transportation. Can be shipped as pure Hydrogen or utilizing a Hydrogen carrier, via ammonia (NH3) and Methylcyclohexane (MCH).

Pipeline Blending

- Hydrogen blending into natural gas pipelines is considered an option to grow hydrogen capability without the large upfront costs and time of developing a dedicated hydrogen pipeline network.

- Hydrogen as a renewable gas, with associated credits, could be important in utilising the North American natural gas pipeline grid.

- SMR in combination with CCS could utilise the North American pipeline grid to provide low/no carbon option.

- Economic incentive for converting excess curtailed energy from renewable sources (wind, solar) into hydrogen.

- Safety is the most important factor for operators of natural gas pipelines throughout North America.

- 2013 NREL study* concluded low concentrations (<5-15% hydrogen by volume) of hydrogen blending in Natural gas pipelines was viable.

- Enbridge Gas received permission from the Ontario Energy Board to blend up to 2% hydrogen** from Electrolysis in Markham, Ontario.

- Hydrogen is lower density than natural gas therefore, requires 30% more pipeline space to delivery the same energy (Btu basis).

* Blending Hydrogen into Natural Gas Pipeline Networks: A Review of Key Issues

** OEB Decision EB-2019-0294

See also:

Hydrogen Steam Methane Reforming (SMR) 2021

Carbon Capture and Storage for Hydrogen 2021

Low Carbon Ammonia Plant 2021

Hydrogen Pipeline 2021

Methylcyclohexane (MHC)-Toluene Hydrogenation 2021